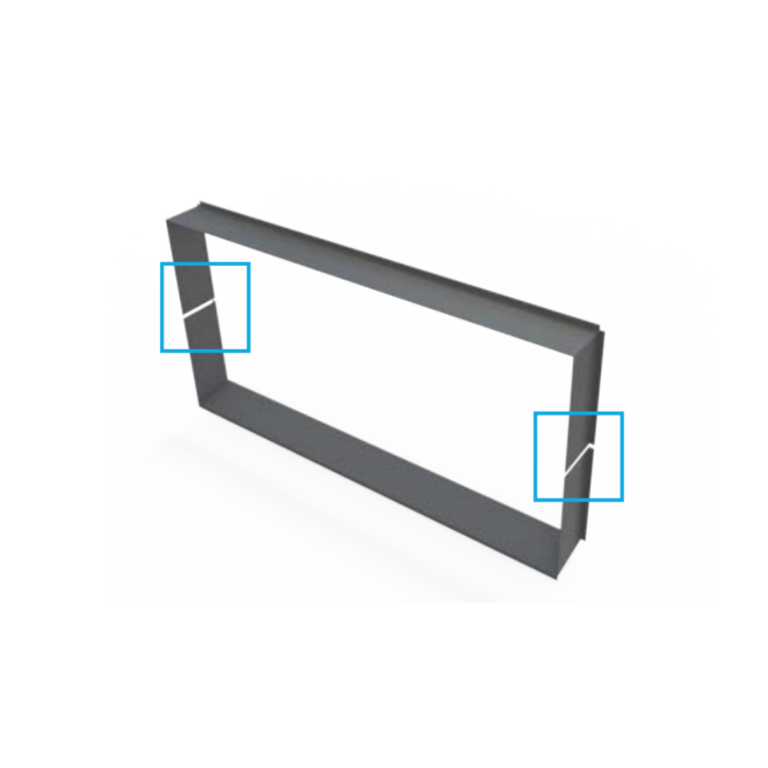

Linking reveals

Does your reveal not fit within the maximum dimensions of 4 m x 2 m? In this case, the frames are divided into several parts. We make sure that the parts are perfectly joined together.

This is where the joints come in: invisible connectors that join the different parts together with precision. But how exactly do they work, and why are they so important for a quality finish?

What is a splicer?

A splicer is an underlying joint used to join parts together. As standard, they are glued invisibly, leaving only the joint line visible. A splicer is always made of 1.5 mm thick aluminium and has the same colour as the aluminium reveal.

How does the joint work?

The joint is designed in the same way as the inside of the reveal, with a small gap to ensure correct bonding. In this way, it adapts perfectly to the sill, side or top.

Installation takes just a few steps:

- The splicers are delivered loose with the Roundal reveals.

- On site, they are glued to the inside rear face of the reveal. For optimum adhesion, we recommend using High Tack adhesive.

- After gluing, the joint is invisible, with only the joint line visible.

This procedure ensures a tight, precise connection between the parts, without the splicer itself being visible.

On request, the splices can be welded on one side for added strength (at an additional cost).

The strength of invisible connections

Joints are discreet, but they play an essential role in the precision and finish of large window frames. Thanks to this assembly technique, the reveals remain aesthetically pleasing and the structure remains stable.

Want to know more about the possibilities? Download our E-book!